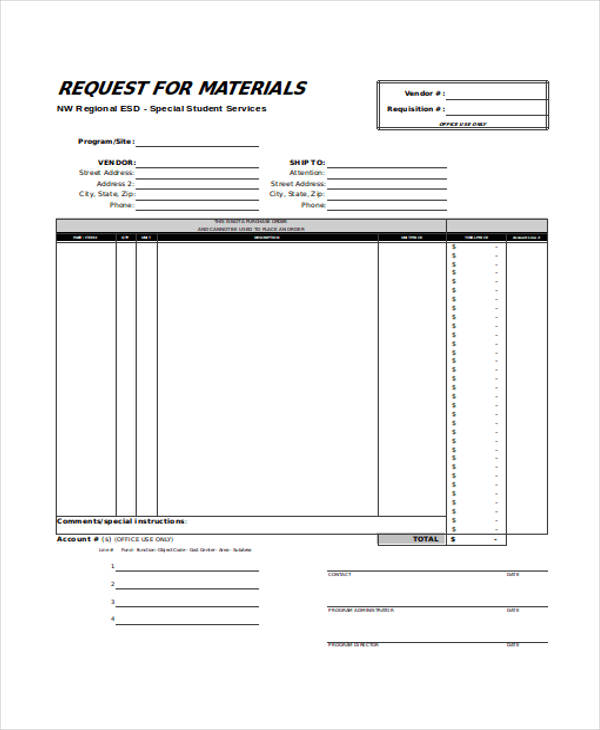

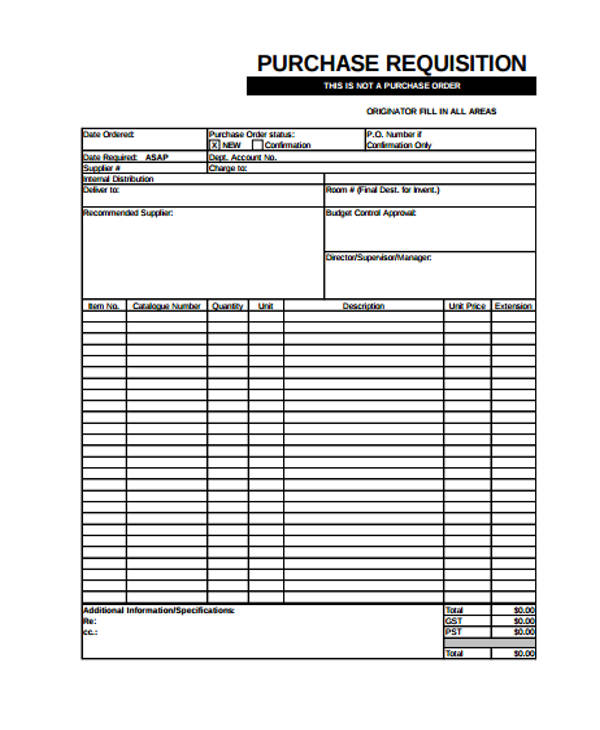

The material requisition form is not used in a computerized production planning environment, where this picking information is instead sent to the warehouse as an electronic message. Like the manager, the purchasing department reviews and approves the requisition. If errors are present or if not enough information is included, the request may be returned to the manager or the requestor for updates. Some organizations may refer to a material requisition form as a purchase requisition form, however, there are some differences. Whenever specific materials are required in a production department, a materials requisition form must be prepared. Whether you need to restock office supplies or lab supplies, Jotform will supply you with the tools you need to organize orders more efficiently.

Flag breakdowns in the material requisition process.

Use this free template to streamline maintenance tracking, ensure reliability, and maintain detailed records for your organization. Track your construction project’s success with our user-friendly Construction Progress Report template. Use this free template to streamline project management, boost efficiency, and keep your construction on track. Ensure your project’s success by leveraging this free, customizable template to effortlessly collect and analyze valuable feedback. For example, when your company orders goods, they are delivered to your warehouse or storage facility, where the appropriate forms are filled out. This provides an audit trail that shows both when goods were purchased and when they were received.

Material Requisition FAQs

The raw materials that are directly traceable to the final product and can be easily and economically assigned to a specific job or production order. In the medical profession, doctors complete a requisition form when requesting lab tests. Provide an approved material list inside your procurement software so teams can efficiently order materials and understand job specs, avoiding costly errors. The requisition process comes with several frequent struggles, from rushed requests to field teams being forced to call vendors directly to delays and higher job spend.

Material Requisition form for Construction

- The process of ordering, storing, and using a company’s inventory, including raw materials, components, and finished products, in a way that minimizes costs and meets customer demand.

- The requisition form is also used to allocate production costs to goods in process, since not all inventories in process will finish in the current year.

- The signature of the person receiving the materials against the materials requisition from the stores must also be obtained by the store-keeper.

- If not, the auditors may conclude that they cannot rely upon certain aspects of a company’s control systems as part of their audit activities, and so will bolster other audit activities.

- This user-friendly form is your go-to tool for visualizing key elements like partnerships, activities, and revenue streams in a snap.

Streamline your equipment requests with our efficient Equipment Request Form template. Easily specify your needs to ensure prompt processing and how to amend a tax return optimized resource allocation. Use this free template to enhance operational efficiency and meet your business’s equipment needs effectively.

What is Material Requisition Form? – Meaning

Dive into detailed insights on process steps, performance metrics, and potential improvements. This easy-to-use checklist template covers everything from pre-travel and packing to departure and arrival. Kickstart your business’s sustainability journey with our user-friendly Business Sustainability Checklist! This handy template covers key areas like energy efficiency, waste management, employee well-being, and more. Seamlessly tailor it to your business needs, ensuring you’re on the path to eco-friendly, socially responsible, and economically sustainable practices.

It’s also used to determine the direct materials used on various jobs or products, along with the indirect materials used by various cost centers. The process of ordering, storing, and using a company’s inventory, including raw materials, components, and finished products, in a way that minimizes costs and meets customer demand. Furthermore, it is the responsibility of the store-keeper to issue the quantity and quality of materials specified in the form.

A gate pass is a document issued in the name of the authority that receives materials from the storage department. The requisition is routed to management for approval, and once received, the system moves to the purchasing process and then finalized once payment is made to the vendor. Another example of a requisition process occurs within the world of finance when shareholders choose to requisition a company’s board of directors to take a vote on proposed resolutions. At its essence, a requisition process is a formalized documented procedure key to improving efficiencies within a business setting. Depending on the size of the company, request forms are filled out weekly, daily, or even hourly. Gate passes issued by a storekeeper authorize the security officer of the storage department to allow the specified person to carry the specified materials out of the store.

A formalized requisition process improves efficiency and accountability across all points of contact. For example, in the medical profession, doctors complete a requisition form when requesting lab tests. The production manager generally fills out the materials requisition form and delivers it to either the materials or storage department where all the raw materials are located. Then, the materials manager approves the request and has the raw materials moved from the storage area to the production floor. The requesting person retains a copy of the material requisition form, as does the warehouse staff. If items listed on the form are not in stock, another copy may be sent to the purchasing department for ordering purposes.

When the production floor needs more materials, it requests them from storage with the materials requisition form. This, again, adds a paper trail to show when the goods were moved from storage to manufacturing. These documents can also help managers determine when to order more materials. For example, if they see that goods are sitting in storage for months before making it into production, they will probably stop ordering those materials so often. A material requisition form is an essential document that allows a business to track inventory levels and order materials from suppliers. Consequently this form is used to request materials from the inventory department for use in a specific job or project.

The signature of the person receiving the materials against the materials requisition from the stores must also be obtained by the store-keeper. The person who is requesting the materials will keep a copy of the form, as will the warehouse staff. Materials requisition is the process of formally requesting and authorizing the withdrawal of materials from an organization’s inventory to be used in the production of goods or the provision of services. It is a crucial component of the job order costing method, as it helps to accurately trace the flow of product costs through the inventory accounts. Allow your employees request for materials in your store with this sample material requisition form.

Betty Wainstock

Sócia-diretora da Ideia Consumer Insights. Pós-doutorado em Comunicação e Cultura pela UFRJ, PHD em Psicologia pela PUC. Temas: Tecnologias, Comunicação e Subjetividade. Graduada em Psicologia pela UFRJ. Especializada em Planejamento de Estudos de Mercado e Geração de Insights de Comunicação.